- What is a ladle filler?

- Ladle is a container to transport the molten steel, which completed melting and refining in a converter or electrical arc furnace, to run secondary refining outside the furnace. The nozzle of sliding gate system is located in the lower part of ladle to release the molten steel.

Ladle filler is a refractory material in particle form to fill the inside of nozzle of sliding gate system. It also enables continuous casting process through releasing the molten steel without any stagnancy or clogging when the nozzle is opened to cast the refined molten steel into the form of billet, bloom, slab, ingot, etc.

- Required characteristics

of the ladle filler -

- Refractoriness at high temperature must be high.

- Must have minimum physical, chemical reaction with the molten steel.

- Must have a good liquidity.

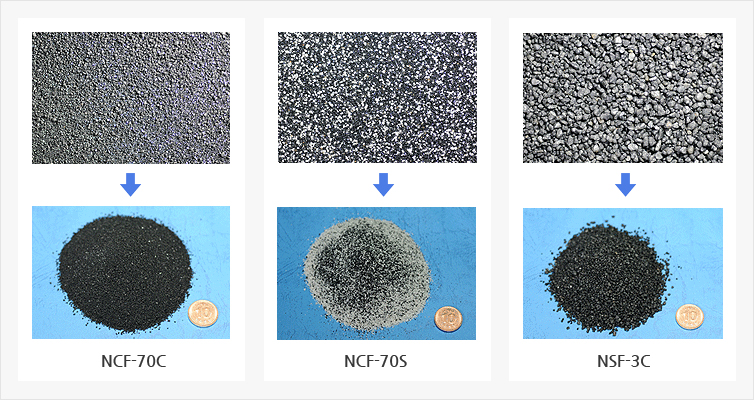

- Particles of the ladle filler

-

- Quality table to the ladle filler

-

Quality table to the ladle filler Kind of filler NCF-60C NCF-70C,NCF-70S NCF-70CM NCF-H70C NCF-80C TS-3, TS-3C Particle

size

(Wt%)+2mm - - - - - -2+1mm 0.5≥ ← ← ← ← ← -1+0.1mm 95.0≤ ← ← ← ← ← -0.1mm 0.5≥ ← ← ← ← ← Bulk density(g/cc) 1.84≤ 2.00≤ ← ← 2.10≤ 1.20≤ Chemical

composition

(Wt%)SiO2 38.0≥ 30.0≥ 31.0≥ 32.0≥ 25.0≥ 90.0≤ Cr2O3 24.0≤ 27.5≤ 28.0≤ 28.5≤ 32.0≤ - Al2O3 13.5≥ 15.0≥ ← ← 18.0≥ 5.0≥ MgO 6.5≥ 7.0≥ ← ← 9.0≥ 1.0≥ Fe2O3 18.5≥ 20.5≥ ← ← 23.0≥ 1.0≥ Na2O+K2O 2.2≥ 2.0≥ 1.5≥ 0.5≥ 1.0≥ 3.0≥ Water 0.3≥ 0.3≥ ← ← 0.3≥ 0.5≥ Carbon coating Coated 70C : Coated,

70S : Non-CoatedCoated Coated Coated Non-coated, Coated